Diamond Light Source Experiment

Posted by: Dr Thomas Barthelay

Rob and I went to Diamond Lightsource in Didcot to help Dr. Alexander Lunt and researcher Sophie Wilson with an experiment using tomography to investigate shaped carbon fibre strands with different vacancies between the individual fibres cope under stress. This experiment was conducted over 5 days, but we were only there for 3 of those (Friday through until Sunday).

Our short trip started on Friday afternoon where we took the Toyota Prius to Didcot, Oxfordshire, which is a small, unassuming town. However, just around the corner is the immense Harwell Science and Innovation park that can only be described as a Disneyland park made for scientists. Not only does it have the Synchrotron, Diamond Lightsource, but it is also home to the European Space Agency ECSAT, the previous Atomic Energy Research Establishment (AERE) and the Rutherford Appleton Laboratories, all which have historical significance in British science and innovation.

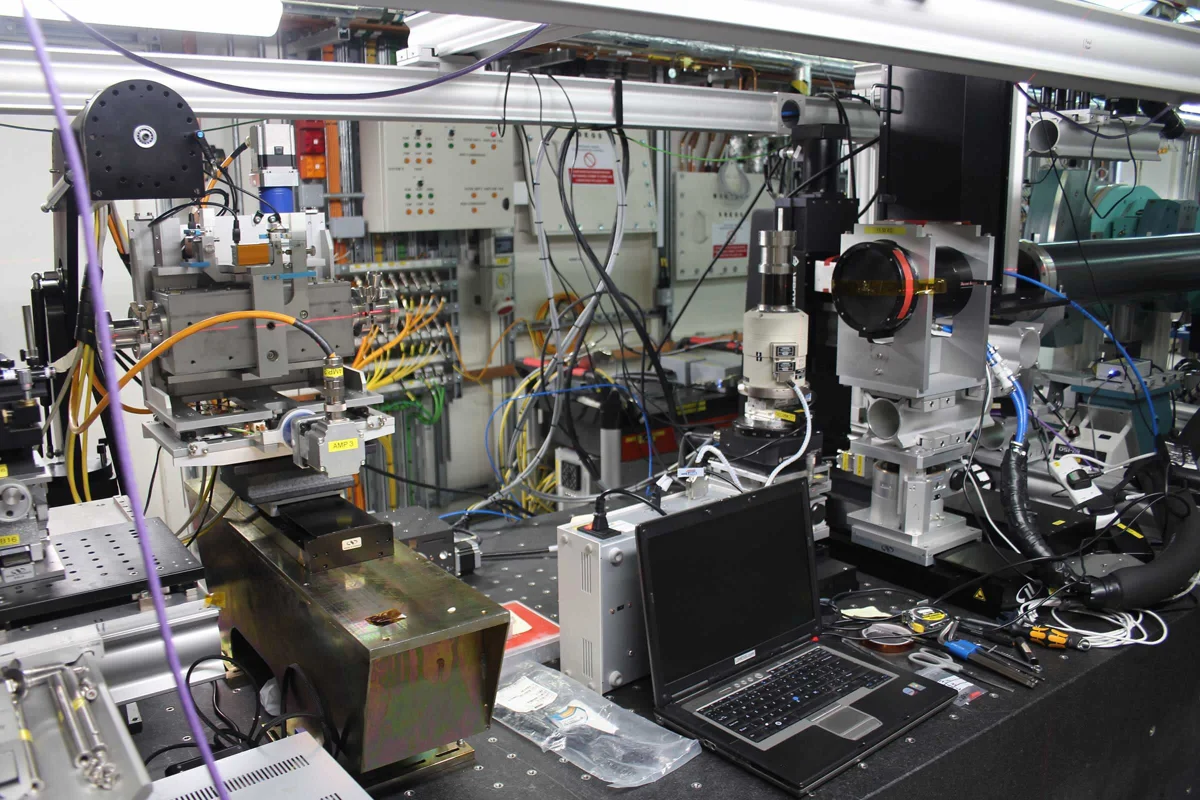

When we finally made our way into Diamond, we parked at one of the many entrances around the circumference of the building, which is hard to find the correct one at first due to the building not having an obvious front door! Diamond Lightsource is a large circular building that uses a linear accelerator (LINAC), which pushes electrons very fast that are bent round and round in a circle using large magnets that are, oddly, called wigglers and undulators. This bending of the electrons releases some energy in the form of X-Rays and other various forms of electromagnetic radiation. These waves are then separated out and are directed into enclosed ‘hutches’ (these are basically large shipping containers that make sure no radiation leaks out), where the they would hit a sample being held. The hutch we were working in was called B16 and specialised in topography.

When we arrived late Friday afternoon, Dr. Lunt, had already set up the experiment, which required lining up the sample with the X-Ray beam, and then coding in movements of various motors in different directions. Two different beams were used on each sample, a white beam and a monochromatic beam. This would allow us to get a 3D image of the carbon fibre, as well as a scattering pattern, which we could then determine the spacing of the graphene sheets inside the carbon fibre. The samples were loaded into a piece of equipment that applied a force onto the sample so we could see what happened on an atomic level when force was applied.

This was a bit intimidating as it is a lot of information to remember and get right as you are not only dealing with microscopic measurements but are also dealing with deadly radiation! Nevertheless, Rob and I learnt as much as we could on that Friday evening to make sure we knew how the experiment would run. We ended up staying until the early hours of the morning to make sure everything ran smoothly and then we were eventually satisfied and went to bed.

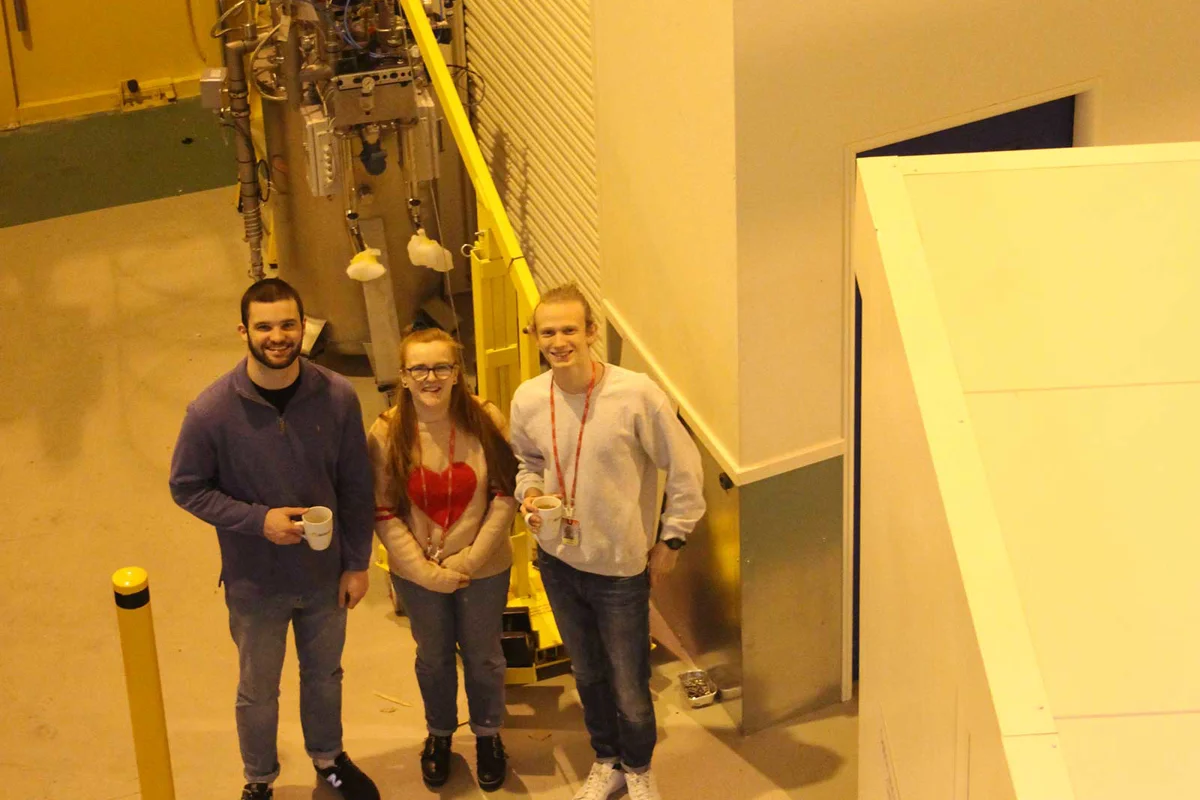

Each experimental run took around 6 hours, which meant that we had to take this in shifts to change the load on the sample and if they broke, change the sample (and of course make sure that nothing had gone wrong!). This resulted in a lot of coffee and tea breaks, but luckily, on the Saturday, Dr. Lunt and our colleague Sophie volunteered the late shift, which meant Rob and I were able to go to bed relatively early that night. However, this also meant that we would be left alone I the morning and had the responsibility to change the sample and re-adjust the sample with the X-Ray beam. This felt like a lot of pressure but had made plenty of notes to make sure we didn’t do anything wrong and eventually felt rather confident and excited that we would be dealing with this amazing piece of equipment ourselves!

Unfortunately, during the night, the wires used for the loading equipment crossed and blocked the equipment. This meant that Dr. Lunt and Sophie had to stay up extra late to sort this out and restart that experimental run. So, when Rob and I woke up the next morning and went to the hutch, we found that there was nothing for us to do immediately. We waited a couple of hours whilst the experiment ran its course and we could start loading the next sample. By that time, however, Dr. Lunt and Sophie were awake despite their late night, which meant that we had help with setting up the next experiment and resulted in less pressure on me and Rob.

Once the experiment was up and running, Rob and I left Dr. Lunt and Sophie and made our way back to Bath that evening as we had to prepare for the upcoming week, which was our Integrative Think Tank (ITT), which you can read about in our next blog by another member of our cohort Vicentiu Lulian-Savu. We left incredibly tired but feeling full of confidence that we had been given the opportunity to work on such a complicated and sophisticated experiment. This was a great experience for us and an amazing chance for us to prepare for our upcoming PhDs where we hope to be visiting the Synchrotron many more times for our own experiments.