Research Trip to KAUST, Saudi Arabia

Posted by: Kacper Kaczmarczyk

Alex Young and I visited King Abdullah University of Science and Technology (KAUST) in Saudi Arabia for the Hydrogen-Based Mobility and Power Conference which was hosted by The Clean Combustion Research Centre (CCRC), followed by an extended research trip.

I spent the 2 weeks following the conference conducting physical experiments on a hydrogen fuel injection converted research engine, of which results I will use to conduct further work for my PhD.

Why experiment?

Hydrogen is still largely an unexplored molecule. This is especially true in the context of utilising hydrogen in simulations of combustion systems, such as Internal Combustion Engines (ICE). Hydrogen ICEs have only recently been accepted as the 3rd potential clean powertrain of the future, amongst more established propositions such as Battery Electric Vehicle (BEV) and Fuel-Cell Electric Vehicle (FCEV).

One of the paramount difficulties in simulating combustion systems is accurately modelling the complex chemical reactions that occur during combustion. In the realm of simulation, various approaches have been developed to tackle this challenge, however, the most employed technique is a reactor model. The appeal of the reactor model lies in its relatively simple mathematical representation, which translates to computational efficiency and cost savings, making it an attractive option for engineering applications.

However, the same simplicity induces the dependence of model’s accuracy on several, non-universal, model inputs, with the most important one being the chemical mechanism, which describes the behaviour of a series of elementary reactions, that make up the global reaction (combustion). Chemical mechanisms are specifically developed to describe specific global reactions, in this case, the oxidation of hydrogen in the presence of air, which is what we use most commonly to simulate hydrogen combustion.

The contents of chemical mechanisms are in theory also very simple. Each of the elementary reaction are first described. For example: H2+O<=>H+OH, where the diatomic hydrogen molecule reacts with a single oxygen atom to produce a single hydrogen atom as well as hydroxide radical which is crucial for the combustion processes of all fuels. Then, the rate of the elementary reaction is described via Arrhenius coefficients. The rate of each elementary reaction is described using Arrhenius coefficients, and this process is repeated for all elementary reactions, which can number in the hundreds when including reactions related to NOx formation that also impacts the combustion process.

The most common and accepted method of finding out the Arrhenius coefficients is to carry out the said reactions in fundamental chemical kinetic experiments. However, systems typically used for such experiments are physically limited to temperatures and pressures that are much lower than what occurs inside combustion systems such as ICEs. Therefore, whenever the chemical mechanism is used to model combustion, we are taking a leap of faith in that we hope that the mechanism extrapolates well at the elevated temperatures and pressures.

To verify the extrapolation, we have devised a plan where we can use a Homogenous Charge Compression Ignition (HCCI) engine, to evaluate state-of-the-art mechanisms at engine-relevant conditions. HCCI combustion mode is governed by chemical kinetics and thus it is accepted by combustion community to use it to investigate reactions and since it’s also an engine, it replicates engine conditions very well.

Additionally, preliminary calculations have shown H2 combustion to be strongly influenced by nitric oxide (NO) as a reactant, in a non-monatomic fashion and as such we have decided to include it in the mechanism evaluation.

The experiment

Prior to my visit, KAUST had already been successful at running their CFR engine in HCCI combustion mode on H2. Therefore, we were confident that we would be able to acquire good data from it.

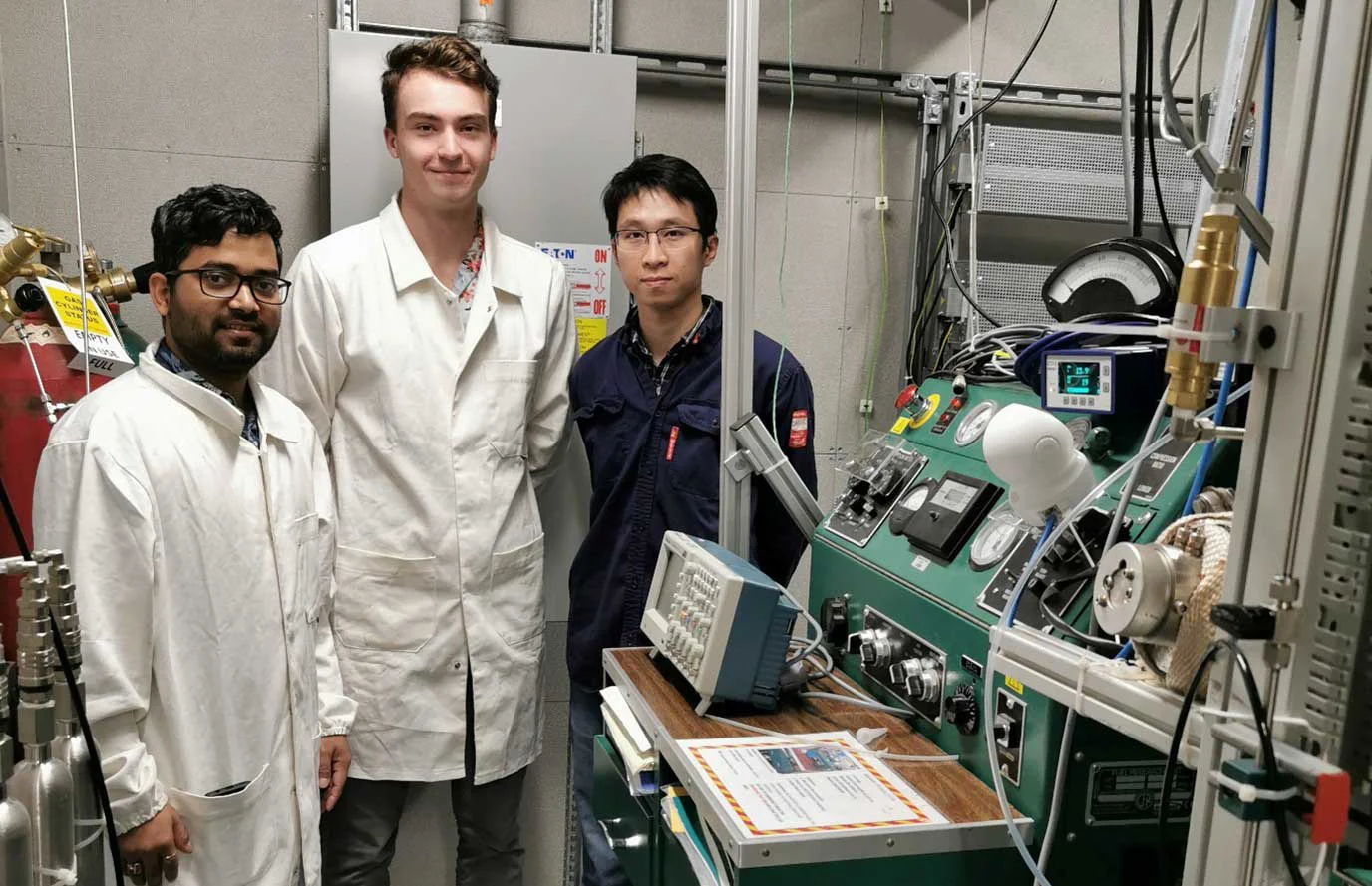

I have worked closely and made very good connections with Dr. Kar (Research Fellow) and Joey (PhD Student) from KAUST shown in Figure 1 above. With their help as well as the state-of-the-art facilities we were able to collect the data we were after, though as is typical, not without problems.

One of these problems revolved around a heat flux sensor that I had taken to KAUST with me. We quickly found out that the CAD model which I’ve used to design an adapter wasn’t accurate, resulting in an adapter that could not physically fit. Though we were able to modify an existing adapter with some help from the machine shop, preliminary runs have shown the sensor to behave unpredictably. While quickly running out of time we had reasons to suspect the adapter to leak, therefore, we decided to mount sensor permanently to the adapter using special ceramic epoxy which seemingly resolved the issue with only few days to spare. After a few days of troubleshooting several problems, we were able to conduct all of the experiments in under 3 days, including using the highly toxic nitric oxide.

We were not only able to collect all the data for my work package, but also, the experiments shown a very interesting combustion behaviour that has not yet been well researched. It was so interesting that Joey has conducted further experiments since to investigate this behaviour and we are currently planning on writing a joined publication regarding this topic.

Success on more than one front

While at KAUST I had a lot of opportunities to make a lot of contacts, from a local PhD student whose H2 flame experiments coincide seamlessly with my planned simulation work, to researchers from industry that were willing to share their data with me.

However, the biggest success aside from the HCCI experiment was the chance to present my research to Prof. Hong and Dr. Xinlei, both of which are CFD experts. In a very challenging 2hr meeting I was able to convince both of my work’s merits. Prof. Hong has since offered me a chance to collaborate with them, as well as access to KAUST’s 200,000 core supercomputer, for the remainder of my PhD. Naturally, I’ve accepted. Thanks to this collaboration my ability to tackle my research problems, as well as the rate at which I work on them, has expanded tremendously. I am extremely thankful of this opportunity.

Conclusion

In conclusion, the 2 weeks I spent at KAUST were highly productive and successful. I conducted a physical with the help of Dr. Kar and Joey using state-of-the-art facilities, despite facing several challenges along the way. The experiment was a success and showed an interesting combustion behaviour that has not yet been well researched. Additionally, I had many opportunities to make contacts with other researchers and present my research to experts in the field. Prof. Hong and Dr. Xinlei were impressed by my work and offered me a chance to collaborate with them in the future, making this visit a huge success on more than one front.